Mitsubishi Electric successfully develops SiC MOSFET based on a new structure

SiC MOSFET based on a novel structure

The new chip structure can effectively prevent surge currents from concentrating on specific chips

News Releases

Mitsubishi Electric has successfully developed

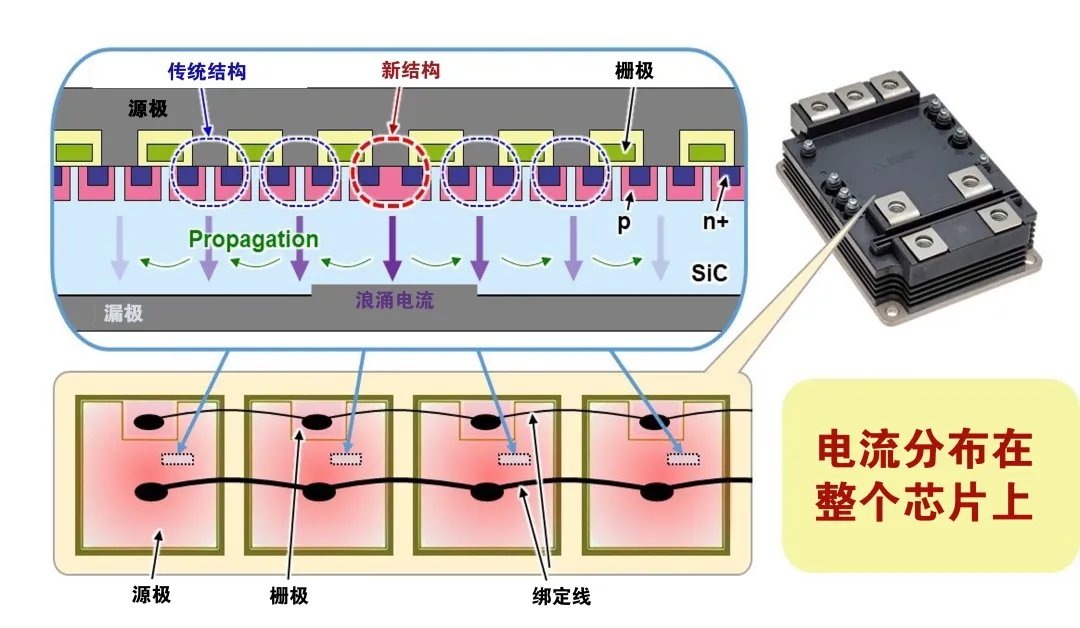

Figure 1: Newly developed chip structure (top: chip cross-section; bottom: parallel chip)

Mitsubishi Electric Group recently announced (June 1, 2023) that it has developed a new SiC MOSFET structure with integrated SBD and has applied it to a 3.3kV all SiC power module - FMF800DC-66BEW, suitable for large industrial equipment such as railways and power systems. The samples will be available for sale starting from May 31st. This new structure chip is expected to help achieve miniaturization and energy saving of electrical systems such as railway traction, promote the popularization of DC power transmission and transformation, and contribute to achieving carbon neutrality.

SiC power semiconductors have attracted much attention due to their ability to significantly reduce power loss. Mitsubishi Electric commercialized SiC power modules equipped with SiC MOSFETs and SiC SBDs in 2010, using SiC power semiconductors in various inverter systems such as air conditioning and railways.

Compared with the traditional method of separating and paralleling chips, the integrated chip that integrates SiC MOSFET and SiC SBD can be more compactly packaged in power modules, thereby achieving miniaturization, large capacity, and lower switching losses of power modules. It is expected to be widely used in large industrial equipment such as railways and power systems. So far, due to the relatively low surge current resistance of SiC MOSFET power modules integrated with SBD, the surge current is only concentrated on certain specific chips, resulting in thermal damage to the chips during high surge currents, thus facing difficulties in practical applications.

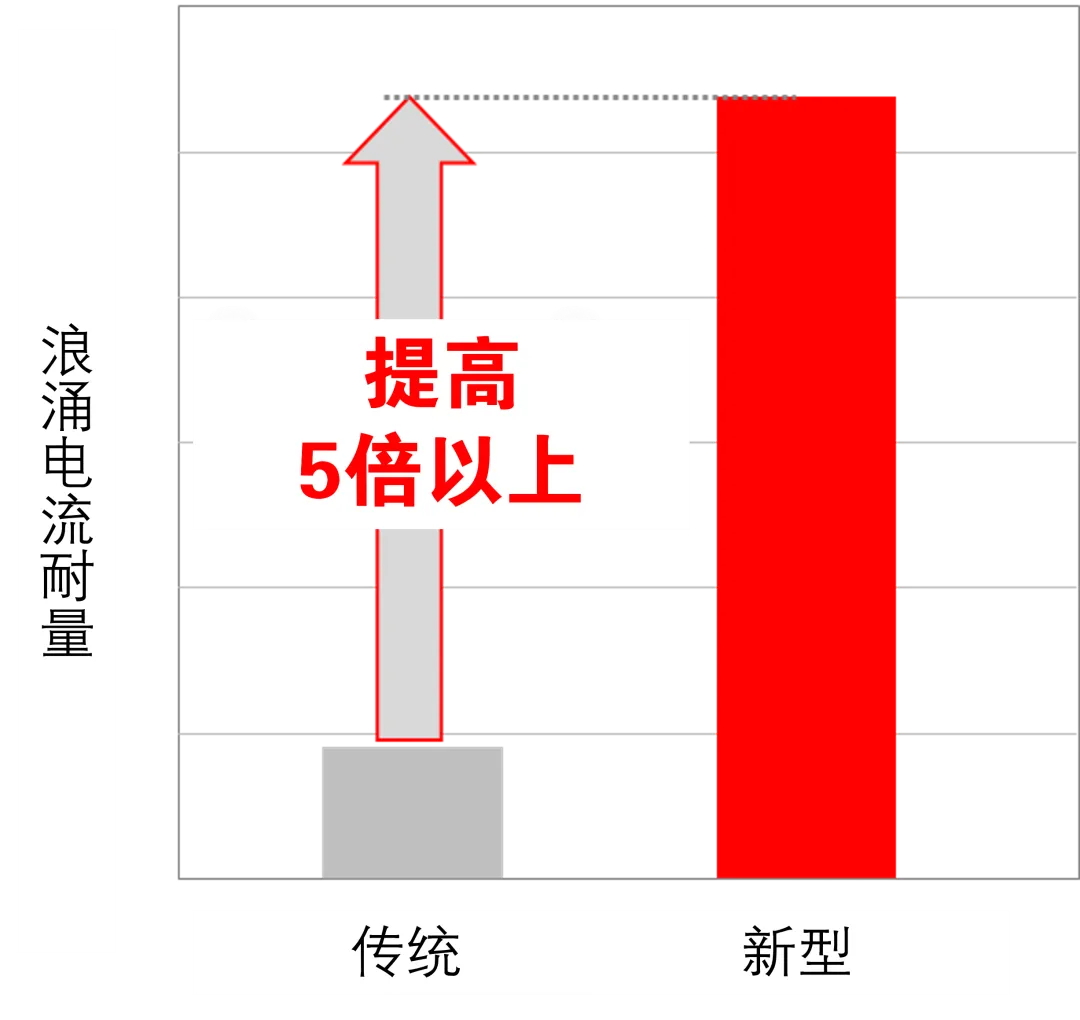

Mitsubishi Electric was the first to discover the mechanism of surge current concentration on certain specific chips inside the power module. A new chip structure has been developed, in which all chips start to flow simultaneously, causing surge currents to be distributed across each chip. Therefore, compared with the existing technology of our company, the surge current resistance of the power module has been improved by more than five times, achieving the same or higher surge current tolerance as the existing Si power module, thus realizing the SiC MOSFET power module integrated with SBD.

The detailed information of this development achievement was published at the ISPSD 2023 (May 28th to June 1st) held in Hong Kong on May 31st at 14:00 (local time).

Future Developments

This new technology will be applied to SiC power modules to achieve miniaturization and energy-saving of railway traction systems. In addition, by using low-power loss converters for direct current transmission, it is expected to achieve lower transmission losses than alternating current transmission, thereby contributing to achieving carbon neutrality.

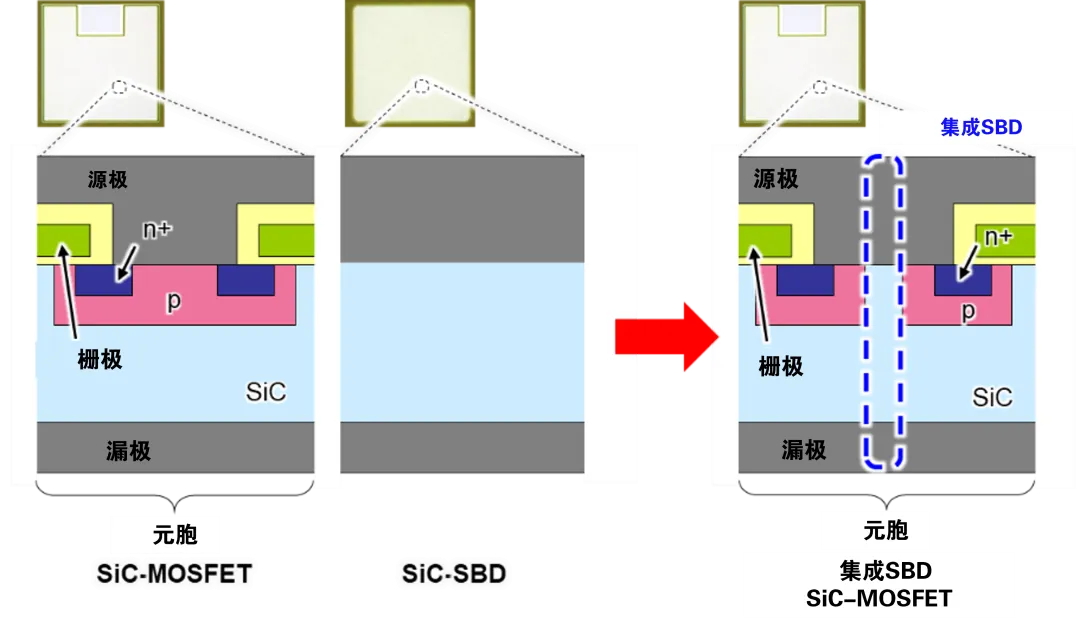

About SBD-embedded MOSFET

In traditional SiC power modules, SiC MOSFETs for switching and SiC SBDs for freewheeling are separately manufactured as two chips and connected in parallel within the module. On the contrary, Mitsubishi Electric's SiC MOSFET integrated with SBD (Figure 2) integrates these two chips by periodically inserting SiC SBDs into SiC MOSFET cells.

Figure 2: SiC MOSFET with integrated SBD realizes the integration of SiC MOSFET and SiC SBD

Features

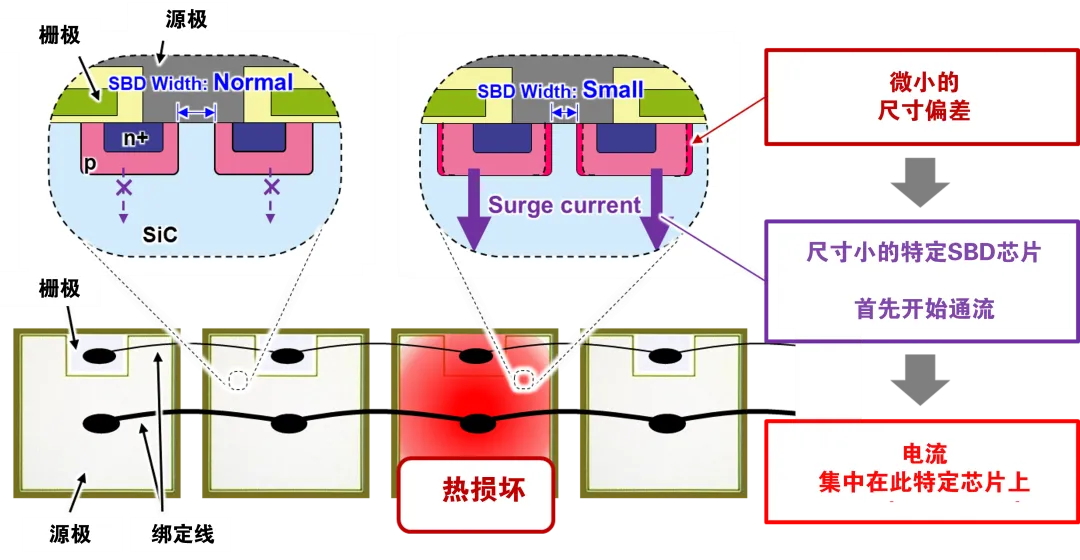

01 Breakthrough Discovery - Mechanism of Surge Current Concentration on Specific Chips

Traditionally, when surge current flows through multiple integrated SBD MOSFET chips connected in parallel, the surge current is only concentrated on certain specific chips, and the surge current tolerance corresponding to the number of parallel chips cannot be obtained. According to the results of physical analysis and device simulation analysis, if the chip size with built-in SBD is slightly different from other chips (with a slightly smaller width, as shown in Figure 3), the surge current will concentrate on that specific chip, causing it to flow before other chips conduct. This size deviation is extremely small and is basically unavoidable in the normal chip manufacturing process.

Figure 3: Mechanism of Current Concentration to Specific Chips in Existing Technology

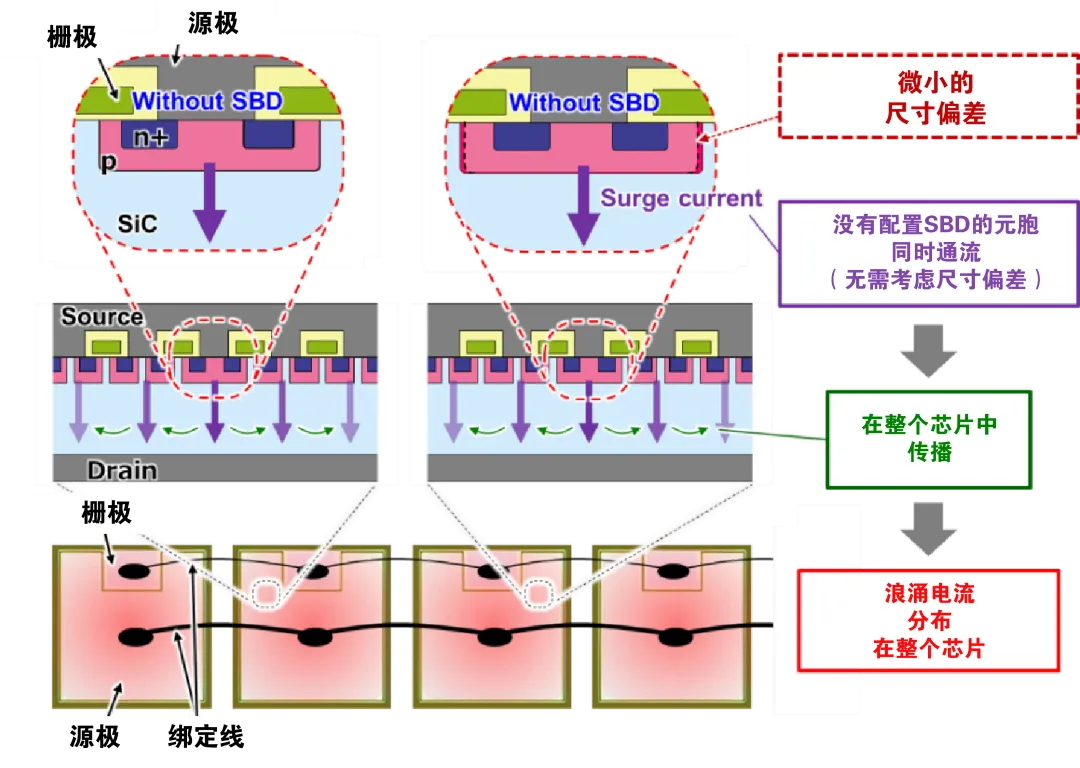

02 New chip structure - all parallel chips conduct simultaneously

In order to prevent surge currents from concentrating on specific chips, Mitsubishi Electric has developed a new chip structure without SBD for cells that account for less than 1% of the total chip area. Compared to other cells configured with SBD, this type of cell can conduct surge currents more quickly and is not affected by small size deviations due to the absence of SBD. Surge current can start conducting simultaneously in the corresponding cells without SBD configuration in all parallel chips.

In addition, due to the surge current reducing the impedance around SiC, it triggers the surrounding cells to start conducting, forming a chain reaction. This phenomenon causes surge currents to propagate throughout the entire chip area starting from cells without SBD configuration. Therefore, the surge current is distributed in all areas of all chips, preventing chip thermal breakdown caused by the concentration of surge current on specific chips, thereby improving the surge current tolerance (Figure 4).

Figure 4: The new structure avoids current concentration on specific chips

03 Enhanced surge current carrying capability - making SiC MOSFET power modules with built-in SBD possible

By adopting this new chip structure, the SiC MOSFET module with built-in SBD has improved its surge current resistance by more than 5 times compared to our existing technology, which is comparable to or even greater than the widely used traditional Si power module. In addition, due to the chain reaction of surge current, cells without SBD only occupy a small part of the total chip area (less than 1%), and will not affect the low on resistance and low switching loss characteristics of the power module due to the reduction of built-in SBD area. Therefore, parallel connection of chips required for high-power modules such as railways and power systems has become possible, realizing SiC MOSFET power modules with built-in SBD.

Figure 5: New technology improves surge current resistance capability

About Mitsubishi Electric

Mitsubishi Electric was founded in 1921 and is a globally renowned comprehensive enterprise. In the 2022 Fortune Global 500 ranking, it is ranked 351st. For the fiscal year ending March 31, 2022, the group's revenue was 4476.8 billion yen (approximately 33.2 billion US dollars). As a technology driven enterprise, Mitsubishi Electric has multiple patented technologies and occupies an important position in the global markets of power equipment, communication equipment, industrial automation, electronic components, home appliances, etc. with strong technical strength and good corporate reputation. Especially in the electronic components market, Mitsubishi Electric has been engaged in the development and production of semiconductors for over 60 years. Its semiconductor products have been widely used in fields such as variable frequency household appliances, rail traction, industrial and new energy, electric vehicles, analog/digital communication, and wired/wireless communication.